Originally Posted by

clocker

Well, so much for being sidelined.

Spent all day yesterday tracking down and solving two vexxing issues, both related as it turns out, to the fuel pump.

Long before my arrival on the project, S. had installed a Supra fuel pump- a popular alternative to the more common Walbro- necessary to provide the higher flow required by the bigger injectors.

At least, this has always been my understanding of what had happened.

Turns out, the pump actually came in the car and S. had merely added a relay/fuse to the wiring.

The wiring turned out to be the root cause of issue #1...intermittent stalling and engine cut out.

We had already spent considerable time/money chasing this through the ignition system...new plugs, wires, HP OptiSpark distributor, ignition module and coil pack...all to no avail.

The stalling continued intermittently and was getting worse.

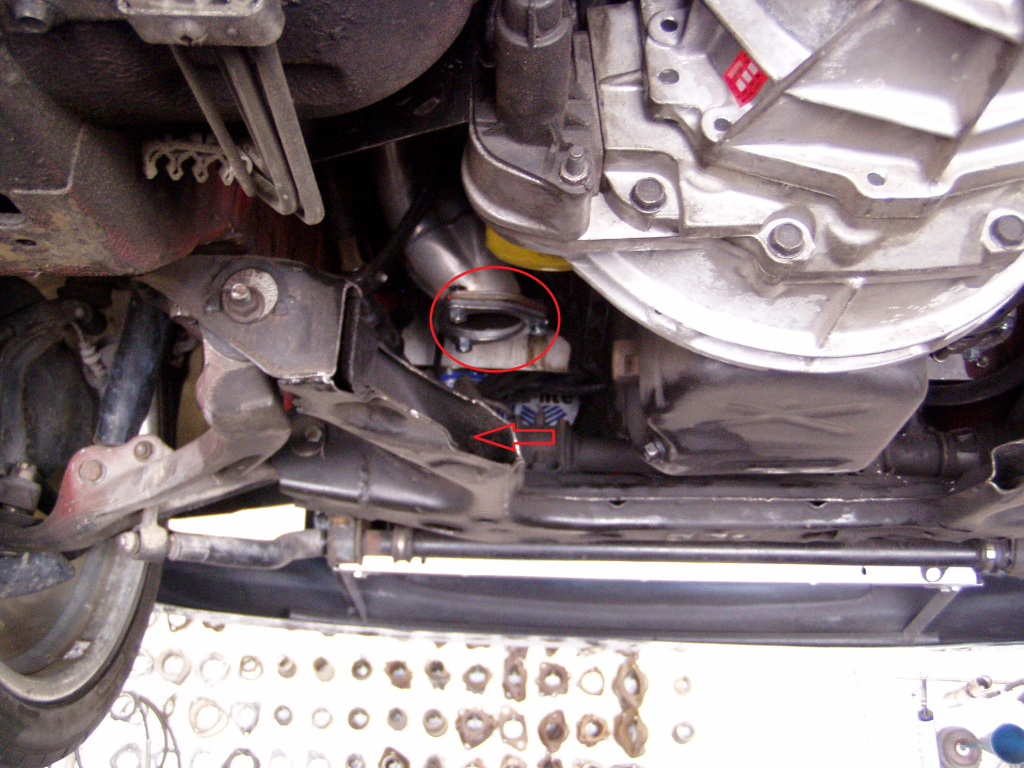

Turns out, the relay assembly S. had installed (buried under the hatch plastics and thus, impossible to get to easily...of course) had an integrated resettable circuit breaker which was malfunctioning and killing power to the fuel pump.

After a few seconds, it would reset and begin working again.

Replaced the relay and installed a real fuse and viola!, problem solved.

The second major issue was a strong fuel smell in the car which we could never localize.

Finally removed the fuelpump access panel and JesusGawd, what a nightmare!

The wiring between the access panel and the pump cover on the tank was a total cobbler's nightmare...the +12v to the pump was bare, twisted wire and the fuel level sender wire was missing altogether (which explains why we could never get the fuel gauge to work) but even worse, there were two open holes drilled into the pump cover.

No clue what what going on here, can't for the life of me imagine how somebody could leave open holes in the gas tank, but there you go.

Used nuts/bolts/fender washers and RTV to plug the holes and surprise, surprise...fuel smell gone!

We have been extremely lucky that the combination of escaping fuel vapor and bare live wires didn't incinerate the car.

Also got the fuel gauge calibrated and working (easily done now that it's finally getting a signal from the tank) and hooked up and calibrated the speedo.

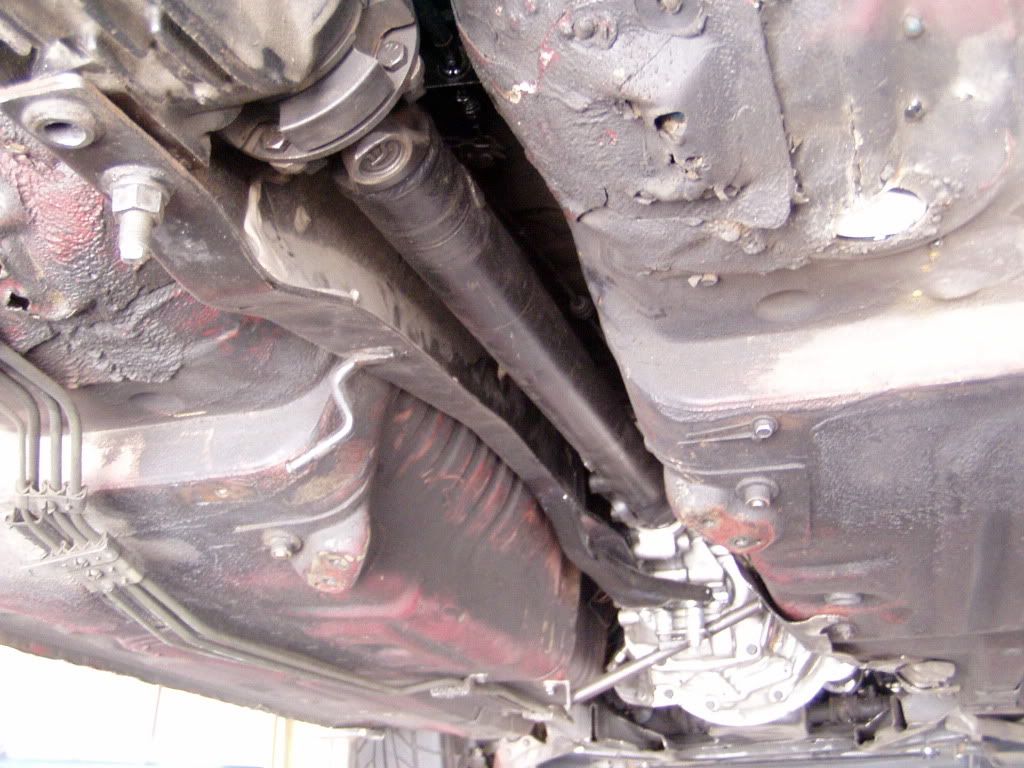

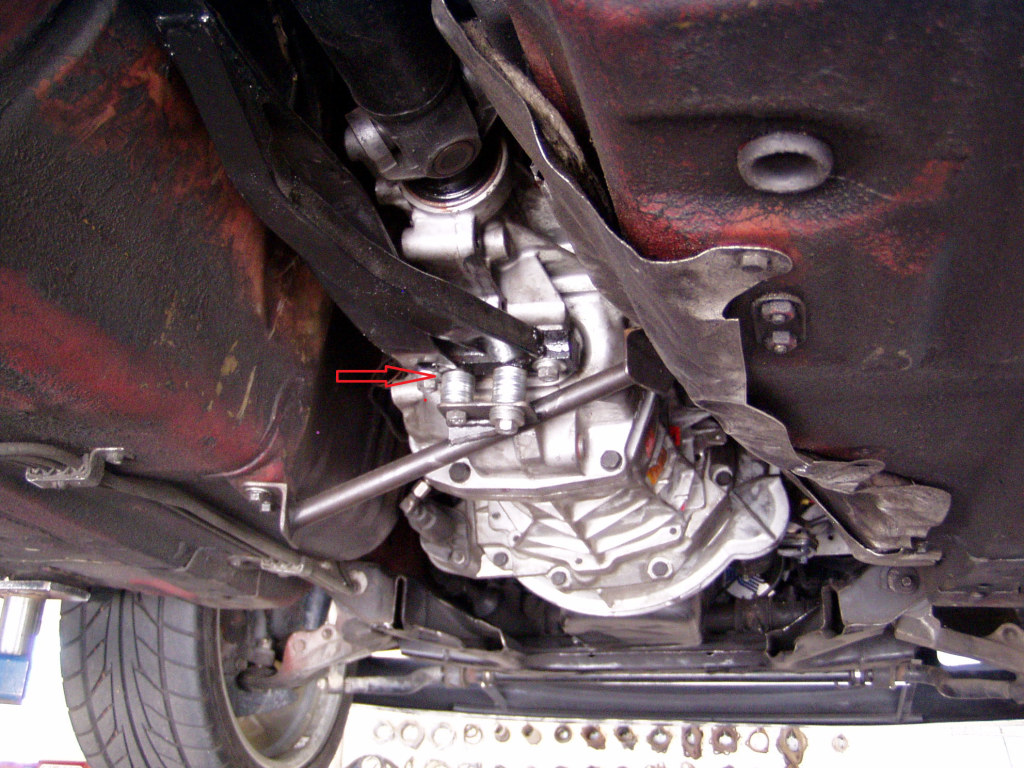

The speedometer was a bit of a trial...the ECU gets the signal from the VSS (vehicle speed sensor) on the transmission and then conditions the signal and sends it on to the speedometer.

Turns out, the Autometer speedo wants the unconditioned signal, it must do it's own processing internally.

Once we tried that, all was good.

Car now pulls strong (real strong!) through 6500 RPMs, which was as high as we dared run her without a tune.

The engine sounds like a bucket of bolts, possibly due to the solid (non-hydraulic) lifters and cheap, stamped metal valve covers.

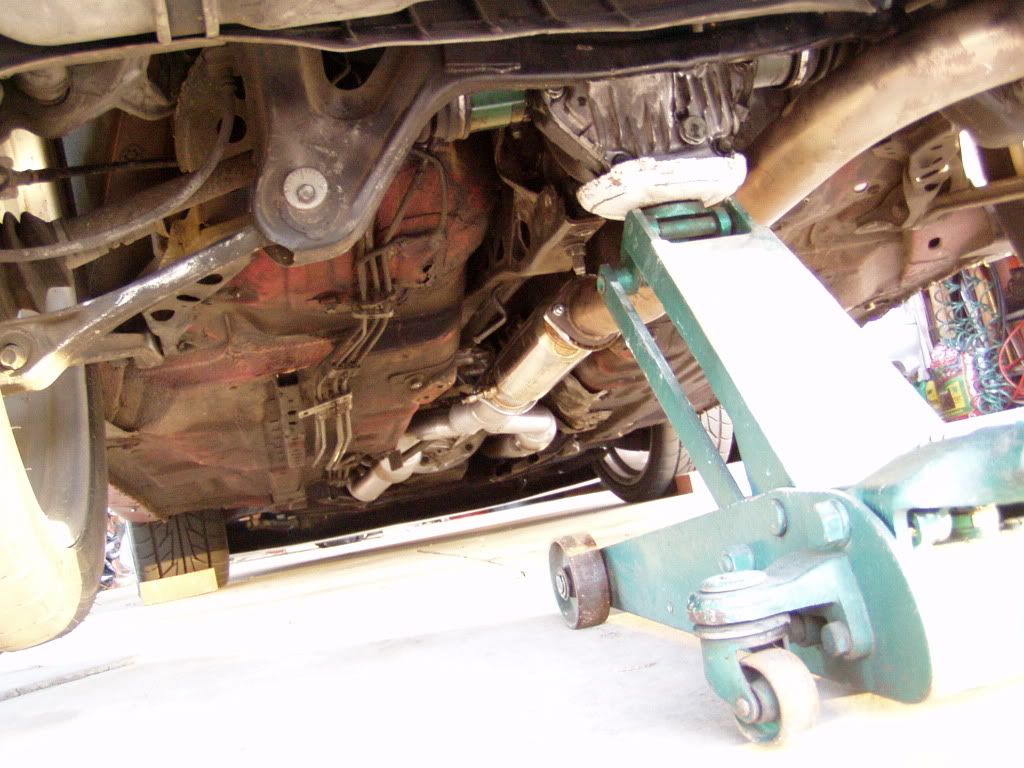

Looking for some cast aluminum valve covers to put on after the valve adjust and I also suspect we have an exhaust leak at the header flange.

We're planning on wrapping the headers (and probably even further down, past the cats) with heat wrap and will replace the gaskets at that time.

All in all though, another great day of progress.

Reply With Quote

Reply With Quote

Bookmarks